We have a wealth of experience in building machinery for the automotive industry, particularly in the assembly and finishing of plastic components.

We work closely with our customers from initial product design to a finished production machine.

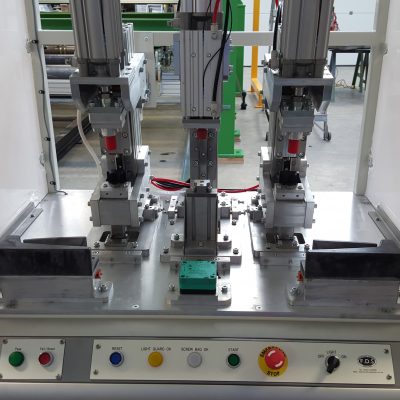

Early in the concept stage we work to identify areas of design that can be improved to make production easier, faster and more reliable. We design workstations with the simplest Poka yoke methods to minimise the risk of faulty parts being produced.

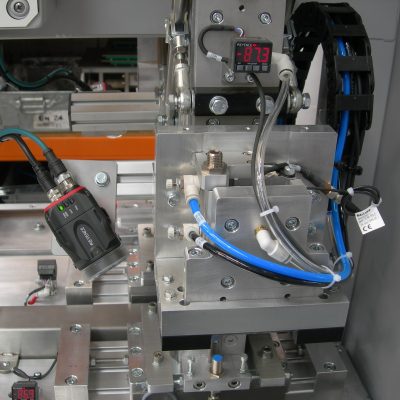

Where advanced methods of Poka yoke are required we are able to incorporate the latest sensing and vision hardware.

Finished machines are tested for compliance with the customer’s capability and uptime.

Examples of Equipment

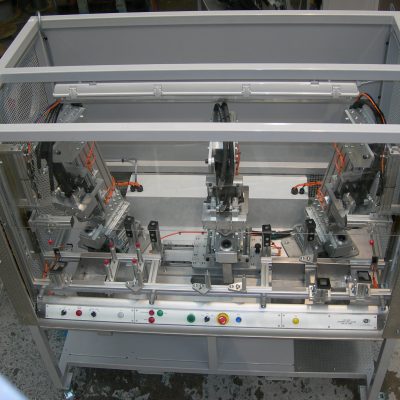

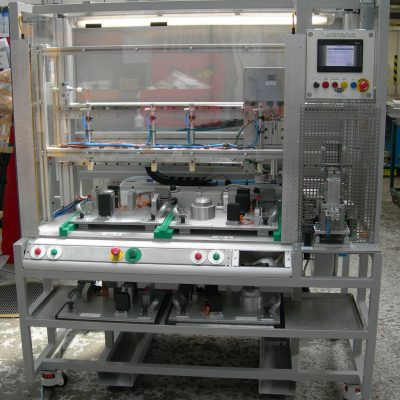

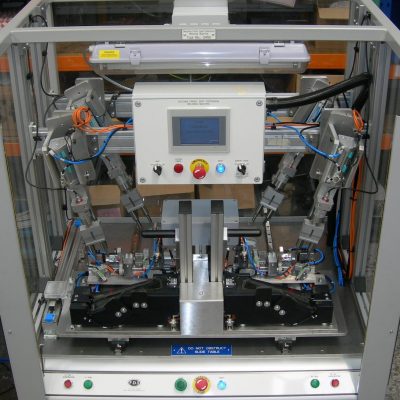

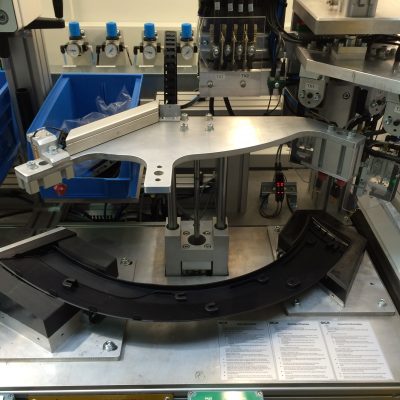

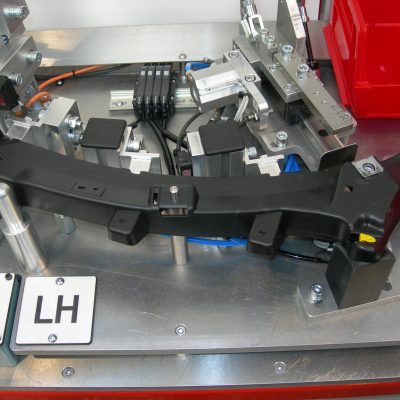

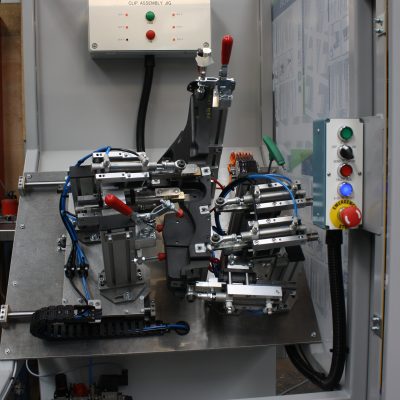

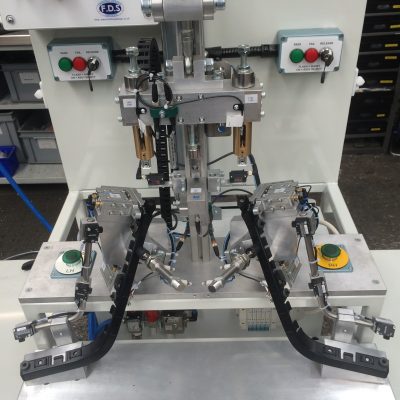

Assembly automation

Ultrasonic welding, hole punching and metal forming

Component assembly

Riveting, screw assembly, inserts and clip installation

Automated and manual assembly cells

Assembly workstations

Ergonomic layout, lighting, work instructions and part storage

Product inspection

Leak testing, pull force testing, vision and part checking systems

Finishing and traceability

1D and 2D bar code printing, etching and laser marking, bar code reading